1. What is EVA Hot Melt Adhesive Film?

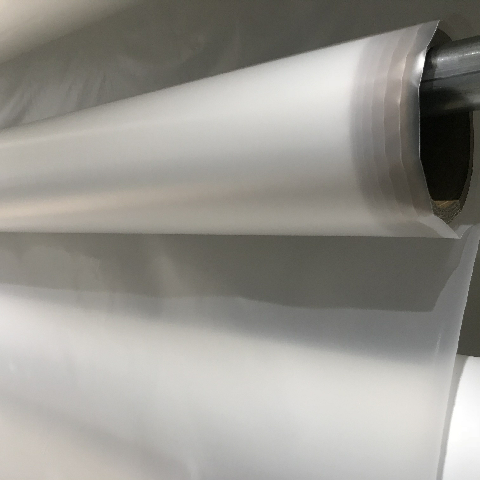

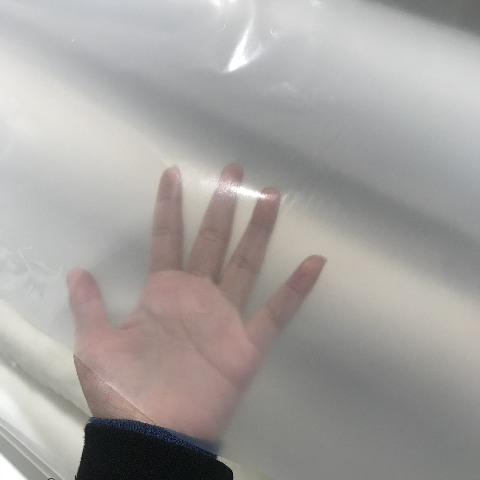

It is a solid, thermoplastic adhesive material supplied in thin film or web form.

Its primary base polymer is Ethylene Vinyl Acetate (EVA) copolymer, typically compounded with tackifying resins, waxes, stabilizers, and other modifiers.

It is activated by heat and pressure, melting to form a strong adhesive bond upon cooling.

2. Key Properties:

Thermoplastic: Melts upon heating and solidifies upon cooling.

Solvent-Free & Eco-Friendly: Contains no volatile organic compounds (VOCs), making it cleaner and safer than solvent-based adhesives.

Fast Bonding: Activation and bonding occur relatively quickly once heat and pressure are applied.

Good Initial Tack: Provides a strong initial grab when molten.

Flexibility: EVA-based films generally retain good flexibility after bonding, conforming well to substrates.

Wide Adhesion Range: Bonds well to various porous and non-porous materials (fabrics, foams, plastics, wood, metals).

Easy Processing: Compatible with standard industrial lamination and bonding equipment.

Cost-Effective: Generally a lower-cost adhesive solution compared to some other HMAM types (like PA, TPU).

3. Primary Applications:

Textile & Apparel:

Laminating fabrics (e.g., interlinings for collars, cuffs, waistbands).

Hemming and seam sealing.

Attaching appliqués, patches, and labels.

Bonding non-woven fabrics (e.g., in hygiene products, filters).

Bonding shoe components like toe puffs, counters, insoles, and linings.

Attaching uppers to midsoles or outsoles (often in combination with other adhesives).

Laminating synthetic leathers and textiles.

Packaging:

Specialty packaging lamination (e.g., paper/foil, paper/plastic).

Sealing cartons and boxes.

Forming rigid boxes.

Automotive & Transportation:

Bonding interior trim components (headliners, door panels, carpets, trunk liners).

Laminating fabrics to foams or composites.

Edge banding and sealing.

Furniture & Upholstery:

Bonding fabric to foam padding.

Edge sealing and lamination in mattresses and cushions.

Laminating decorative surfaces.

Technical Textiles & Industrial Laminates:

Bonding layers in filtration media.

Laminating geotextiles.

Creating composite materials for various industrial uses.

DIY & Crafts: (Lower melt point variants)

Bonding materials for hobby projects.

Fabric crafts and embellishments.

4.Processing Methods:

5.Flatbed Lamination: Using heated platen presses.

Continuous Roll Lamination: Using heated calendar rollers or nip rollers.

Contour Bonding: Using specialized heated tools for specific shapes.

Ultrasonic Activation: Using ultrasonic energy to melt the film locally (less common for EVA than other types).

Process: Place the film between substrates -> Apply heat (melting the film) -> Apply pressure (ensuring contact & wetting) -> Cool (solidification and bond formation).

6. Advantages of EVA HMAM:

Clean and easy to handle (no mess, dust-free).

Consistent thickness and adhesive distribution.

No drying/curing time required after bonding.

Excellent storage stability under normal conditions.

Good balance of adhesion, flexibility, and cost.

Relatively low processing temperatures compared to some HMAMs.

6. Limitations/Considerations:

Temperature Sensitivity: Bonds can soften or fail at elevated temperatures (typically limited to <~65-80°C / 150-175°F continuous use, depending on formulation).

Chemical Resistance: Generally poor resistance to solvents, oils, and strong chemicals.

Creep: Under constant load, especially at higher temperatures, bonded parts may creep (slowly deform).

Moisture Resistance: Performance can be variable depending on formulation; not inherently waterproof like some PUR films.

Substrate Compatibility: While broad, adhesion to very low surface energy plastics (like PP, PE) often requires surface treatment or specific formulations.

Conclusion:

EVA Hot Melt Adhesive Film is a versatile, cost-effective, and user-friendly bonding solution widely used across textiles, footwear, packaging, automotive interiors, furniture, and industrial lamination. Its key strengths lie in its ease of processing, good flexibility, strong initial tack, and solvent-free nature. While its temperature and chemical resistance impose some limitations, it remains a dominant choice for applications where these factors are not critical and cost-effectiveness is paramount.

Post time: May-29-2025